- HOME

- Reason of Choosing

- Diverse facilities

Reasons for Choosing 02Diverse facilities

Our manufacturing facilities are multipurpose. We address a broad range of customers’ needs with accuracy, flexibility, and swiftness, including provision of several grams of sample through commercial production of several dozen tons of product.

Facilities

2. Laboratory research (30 to 5,000 mL)

Reactor vessels and separatory flasks (30 to 5,000 mL), SUS autoclave (100 to 3,000 mL), Glass-lining autoclave (300 to 1,000 mL), SUS Press filter (200 mL), Glass-lining press filter(1 L), Rectifying column, Thin-film evaporator, Pure water system, Ultrapure water system, Constant temperature and humidity oven, Refrigerant device (minimum -15 ℃), Vacuum dryer, Homogenizer, Light flow synthesizer, Syringe pump, etc.

Laboratory

Laboratory Thin-film evaporator

Thin-film evaporator Rectifying column

Rectifying column

3. Kilo lab (10 to 50 L)

Reactor vessels (10 to 50 L), Mantle heater, Separatory flasks (10 L), SUS Press filters(1.5 to 10 L), Nutsche funnel (300 mm diamete), Glass filter (185 mm diameter), Vessels (up to 100 L), etc.

4. Pilot plant (50 to 2,000 L)

Fukui Research Institute (pilot plant)

Fukui Research Institute (pilot plant) Inside of Fukui Research Institute (three stories)

Inside of Fukui Research Institute (three stories) Thin-film evaporator

Thin-film evaporator Reactor (Hastelloy)

Reactor (Hastelloy) Autoclave (Ni cladding)

Autoclave (Ni cladding)

- Pilot plant

-

Equipment Type Material Size Temperature Pressure Reactors Autoclave GL 100 L, 500 L Max. 150 °C Max. 0.8 MPa Ni cladding 200 L Max. 260 °C Max. 0.8 MPa Reactor HS 200 L Max. 150 °C Ambient pressure GL, SUS 50-2000 L Max. 130~150 °C Ambient pressure Filters Centrifuge ETFE 24, 36 inches Press Filter

(vertical single plate type)PTFE, GL 50 L Filter area: 0.125 m3 Max. 0.2 MPa Dryers Conical Dryer GL 300 L, 1000 L Max. 80 °C Max. 10 hPa Distillation and

Extraction ColumnRectifying Column SUS 200 Φ x 4000 H Max. 190 °C Max. 5 hPa Thin-film evaporator SUS 0.4 m3 Max. 200 °C Max. 1 hPa Extraction Column Ion Exchange Column FRP 20 L, 50 L Electrical conductivity : 0.1 mS/m or less

5. Trial production (3,000 to 12,000 L)

6. Commercial production (3,000 to 12,000 L)

Reactors

Reactors Thin-film evaporator

Thin-film evaporator Conical Dryer (inside cleanroom)

Conical Dryer (inside cleanroom) Centrifuge

Centrifuge LNG Satellite Station

LNG Satellite Station Incinerator and Activated sludge facility

Incinerator and Activated sludge facility

- Wakayama Site

-

Equipment Type Material Size Number Temperature Pressure Reactors Autoclave GL 5 m3 3 Max. 160 °C Max. 0.44 to 0.98 MPa 8 m3 2 Max. 150 °C Max. 1.0 MPa SUS 7 m3 2 Max. 160 °C Max0.98 MPa Reactor GL 3 m3 2 Ambient temperature to Max. 160 °C Ambient pressure 5 m3 2 Max. 160 °C Ambient pressure 7 m3 1 Max. 150 °C Ambient pressure 8 m3 12 Max. 150 to 160 °C Ambient pressure 10 m3 5 Max. 150 to 160 °C Ambient pressure 12 m3 7 Max. 150 to 160 °C Ambient pressure SUS 5 m3 2 Max. 150 to 160 °C Ambient pressure 7 m3 5 Max. 150 to 160 °C Ambient pressure 8 m3 8 Max. 150 °C Ambient pressure 9 m3 2 Max. 130 °C Ambient pressure 10 m3 1 Max. 160 °C Ambient pressure 15 m3 1 Max. 130 °C Ambient pressure 16 m3 1 Max. 130 °C Ambient pressure Filters Centrifuge ETFE 48 x 30 inches 2 Max. 80 to 100 °C 48 x 38 inches 2 Max. 100 °C SUS 48 x 30 inches 1 Max. 100 °C RL 48 x 30 inches 2 Max. 100 °C Pressure leaf Filter ETFE 300 L 2 Max. 100 °C ETFE 500 L 2 Max. 100 °C Single plate type SUS 300 L 2 Max. 100 °C Filter Press PP 0.25 m3 1 Max. 80 °C 1 m3 1 Max. 80 °C Dryers Horizontal mixing dryer SUS 3 m3 2 Max. 150 °C Max.Vacuum 0.4 kPa HS 3 m3 1 Conical Dryer GL 3 m3 1 Max. 95 °C Tray type SUS 500 kg 2 Max. 80 °C (warm air) Ambient pressure Pulverizer Mesh screen SUS large 1 small 1 Sieve vibratory type SUS small 1 centrifugal type SUS/PE Mesh big 1 Packaging machine scew feeders SUS 300 kg 2

- Fukui Site

-

Equipment Type Material Size Number Temperature Pressure Reactors Autoclave GL 4 m3 1 Max. 150 °C Max. 0.97 MPa 5 m3 1 Max. 130 °C Max. 0.48 MPa 8 m3 4 Max. 140 to 175 °C Max. 0.19 to 0.98 MPa 10 m3 2 Max. 140 °C Max. 0.98 MPa SUS 6 m3 1 Max. 150 °C Max. 0.97 MPa 8 m3 1 Max. 140 °C Max. 0.98 MPa 12 m3 1 Max. 150 °C Max. 0.97 MPa HS 4 m3 1 Max. 150 °C Max. 0.70 MPa Reactor GL 3 m3 1 Max. 140 °C Ambient pressure 5 m3 3 Max. 130 to 140 °C Ambient pressure 6 m3 3 Max. 150 to 170 °C Ambient pressure 8 m3 15 Max. 130 to 165 °C Ambient pressure to Max. 0.20 MPa 10 m3 6 Max. 120 to 140 °C Ambient pressure to Max. 0.19 MPa 12 m3 4 Max. 130 to 150 °C Ambient pressure to Max. 0.20 MPa SUS 2 m3 1 Max. 150 °C Max. 0.29 MPa 5 m3 2 Max. 140 to 170 °C Ambient pressure 6 m3 1 Max. 150 °C Ambient pressure 7 m3 1 Max. 150 °C Max. 0.19 MPa 8 m3 4 Max. 140 to 170 °C Ambient pressure 9 m3 1 Max. 40 °C Ambient pressure 12 m3 3 Max. 100 to 150 °C Ambient pressure to Max. 1.0 MPa 14 m3 1 Max. 40 °C Ambient pressure 35 m3 1 Max. 0 °C Ambient pressure Filters Centrifuge ETFE 48 x 20 inches 2 Max. 80 °C Ambient pressure 48 x 30 inches 4 Max. 80 °C Ambient pressure 48 x 38 inches 2 Max. 80 °C Ambient pressure SUS 48 x 30 inches 1 Max. 80 °C Ambient pressure Candle type filter SUS 3㎡ 3 Max. 80 to 150 °C Max. 0.30 to 0.49 MPa Leaf filter SUS 5㎡ 1 Max. 80 °C Max. 0.49 MPa Single plate filter SUS 2 to 3 m3 2 Max. 40 to 100 °C Max. 0.30 to 0.35 MPa Dryers Conical Dryer GL 2 to 3 m3 3 Max. 90 to 100 °C FV Horizontal mixing dryer SUS 4 m3 1 Max. 150 °C FV Vertical mixing dryer SUS 3 m3 1 Max. 130 °C FV SUS 3 m3 1 Max. 100 °C FV Rectifying Column - SUS 356 mm diamter 17 stage 1 Max. 151.1 °C Ambient pressure - SUS 700 mm diamter 26 stage 1 Max. 151.1 °C Ambient pressure Thin-film evaporator - SUS 24-30 thin-film evaporator 1 Max. 300 °C Max. 0.13 kPa Ultrapure Water System - FRP (storage tank) with manufacturing capacity 0.5 m3/hr 1

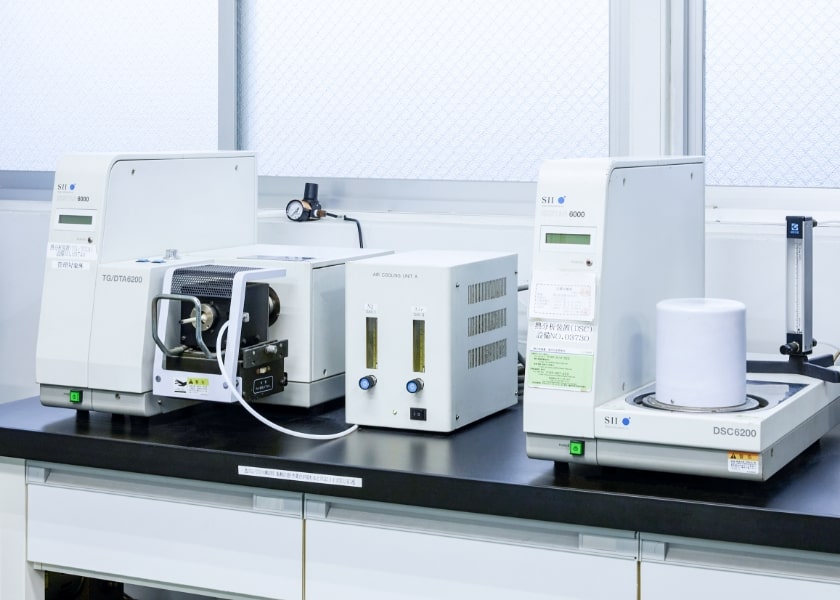

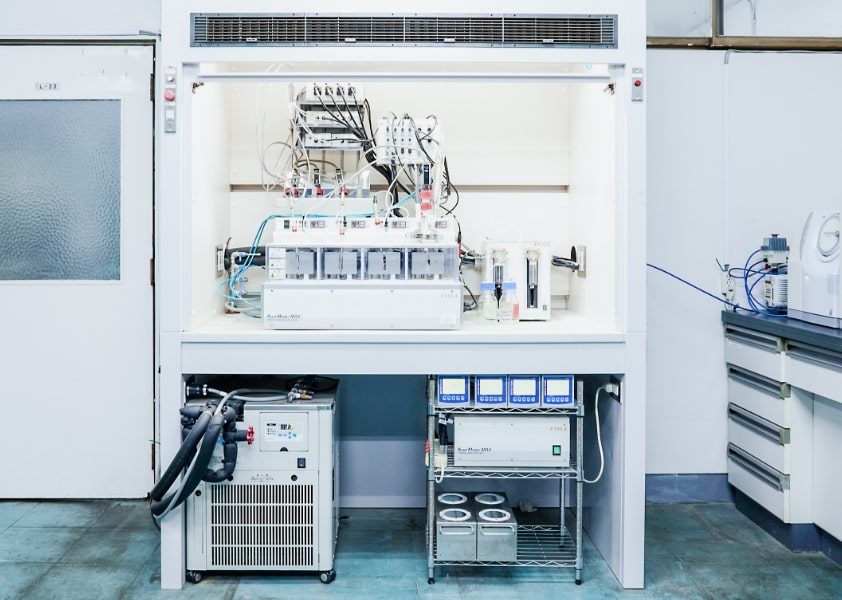

Analytical instruments

HPLC, GC, GPC, GC-MS, LC-MS, DSC, TG/DTA, IC, Reaction calorimeter, Atomic absorption spectrophotometer, Combustion ion chromatography, IR moisture meter, Karl Fischer moisture meter, pH meter, B-type viscometer, UV spectrophotometer, IR spectrophotometer, Digital microscope, Automatic titrator, Colorimeter, Turbidity meter, Total organic carbon (TOC) meter, Conductivity meter, Vacuum dryer, Electric furnace, Pure water system, Ultrapure water system, etc.

HPLC

HPLC LC-MS

LC-MS GC

GC DSC, TG/DTA

DSC, TG/DTA Reaction calorimeter

Reaction calorimeter GC-MS

GC-MS GPC

GPC